A high-performing process control room depends on a precise, end-to-end approach. These centers need to factor in reliability, safety, regulatory compliance, and operator performance.

What Is Process Control?

In utility environments, process control refers to the centralized monitoring and management of complex systems such as power generation, transmission, distribution, and supporting infrastructure to ensure safe, reliable, and compliant operations. Process control rooms enable operators to detect issues, coordinate responses, and maintain continuous service across the grid.

At Constant, we have 40+ years of experience designing, integrating, and supporting mission-critical control centers. Through that experience, the most successful projects follow a structured lifecycle from concept through commissioning and beyond.

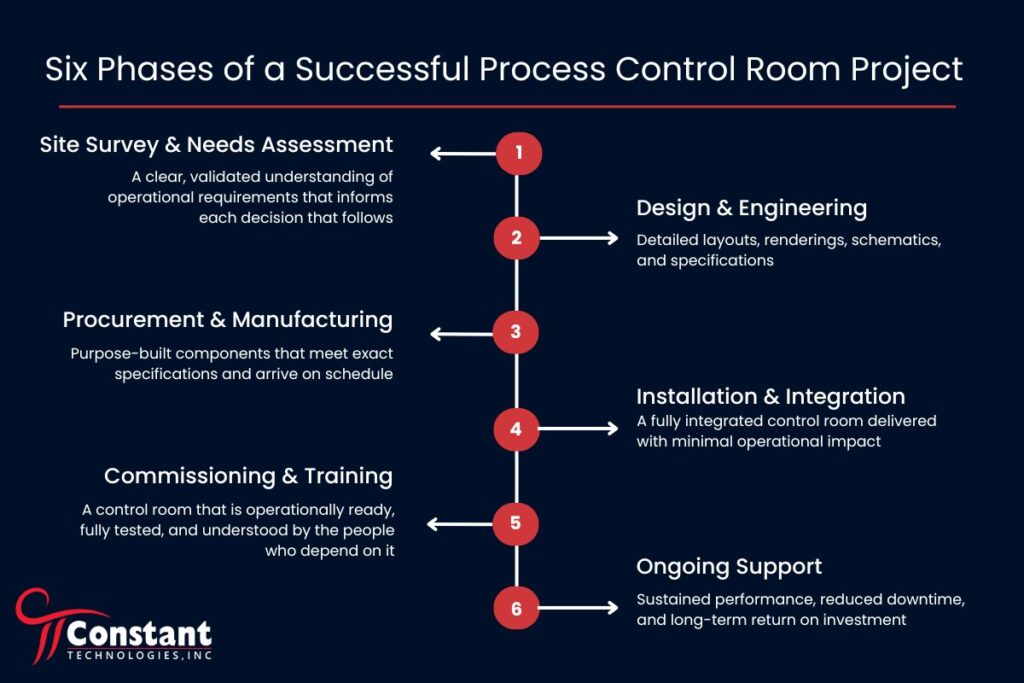

Below, we outline six phases that consistently lead to predictable outcomes, reduced risk, and long-term operational value.

Phase 1: Site Survey and Needs Assessment

Successful control room projects begin with a thorough understanding of how the operation actually works, not how it is assumed to work on paper.

This phase focuses on:

- Existing facility conditions and infrastructure

- Operational workflows and staffing models

- SCADA, EMS, OMS, and supporting systems

- Regulatory and compliance requirements (NERC, ERCOT, CIP, internal standards)

- Future growth and redundancy needs

For utility control rooms, this step is particularly critical. We routinely encounter environments where legacy infrastructure, space constraints, or incremental technology additions have created inefficiencies over time. A detailed site survey allows us to identify those constraints early and avoid downstream redesigns or costly change orders.

Phase 1: A clear, validated understanding of operational requirements that informs each decision that follows.

Phase 2: Conceptual Design and Engineering

With requirements defined, the project moves into conceptual design and engineering. This is where operational needs are translated into a functional, buildable control room.

Key considerations include:

- Room layout and sightlines

- Video wall sizing, placement, and content strategy

- Console configuration and ergonomics

- Acoustic, lighting, and environmental factors

- Technology architecture and system interoperability

Within control rooms, conceptual design often balances immediate operational demands with long-term resilience planning for additional feeds or future system upgrades, without requiring a full room rebuild.

At Constant, this phase is collaborative. Designs are reviewed with stakeholders early and often, ensuring operators, IT, facilities, and leadership are aligned before procurement begins.

Phase 2: A detailed, purpose-built design that supports operators today while remaining adaptable for tomorrow.

Phase 3: Procurement and Manufacturing

Once designs are approved, precision matters. Control rooms are engineered environments that integrate specialized furniture, technology, and infrastructure into a cohesive operational system.

This phase includes:

- Procurement of mission-critical technology components

- Custom manufacturing of consoles

- Quality control and specification verification

- Coordination across vendors to maintain schedule alignment

As a single-source provider, Constant manages this complexity on behalf of the client. This approach reduces integration risk and ensures each component arrives ready to perform within the overall system design.

Phase 3: Purpose-built components that meet exact specifications and arrive on schedule.

Phase 4: Installation and Integration

Utility control room installation and integration often occur within live operational environments, requiring coordination around existing dispatch functions and phased cutovers. Experienced professionals are essential to ensure systems are deployed without disrupting mission-critical operations.

This phase includes:

- Console and video wall installation

- KVM, AV, and network integration

- System configuration and validation

- Close coordination with utility IT and operations teams

Our installation teams specialize in mission-critical environments. They understand that uptime, safety, and operational continuity are essential. Installations are sequenced to minimize disruption and ensure a controlled transition to the new environment.

Phase 4: A fully integrated control room delivered with minimal operational impact.

Phase 5: Commissioning and Training

Through commissioning and training, the control room is validated as operationally ready, enabling operators to perform with confidence from day one.

Commissioning involves:

- System testing and calibration

- Validation of redundancy and failover scenarios

- Performance verification against design intent

- Operator and administrator training

For process control rooms that operate 24/7, this phase ensures there are no surprises once the room goes live. Training is tailored to actual workflows, so operators are confident using the space under real-world conditions.

Phase 5: A control room that is operationally ready, fully tested, and understood by the people who depend on it.

Phase 6: Ongoing Support

Commissioning transitions the control room from implementation to sustained operational use.

Ongoing support may include:

- Preventive maintenance programs

- Technology refresh planning

- Remote monitoring and troubleshooting

- On-call support for critical systems

Utilities evolve, regulations change, and technology advances. Long-term support ensures the control room continues to perform as intended.

Phase 6: Sustained performance, reduced downtime, and long-term return on investment.

What This Approach Delivers

A structured, six-phase approach reduces uncertainty, supports informed decision-making, and ensures each phase builds logically on the last. The result is a control room that is purpose-built, expertly implemented, and prepared to support reliable operations, emergency response, and regulatory requirements over time.

Ready to Plan Your Control Room?

If you are evaluating a new process control room or planning an upgrade to an existing environment, request a consultation to discuss how Constant can help take your project from concept to commissioning, with support at every step.